First thing first, Ducati and Bugatti are two different companies came so shockingly to me. For some reason I had always assumed them to be from the same parent company. And why? It is simple, it RHYMES!

Ducati is easily one of the most reputed motorcycle manufacturers around the globe. Maybe because of its Italian root? I don’t know. The first thing when I hear Italy, is NOT smooth sailing boats in the water streets of Venice, but breathtaking crimson red color Ducati blazing past on the racetrack. Ducati is luxury for the even the most luxurious people you might know. These Superbikes are deservingly premium and purposely very heavy on pockets.

Walk me through an engine first?

To understand the big fuss about Ducati, one needs to understand a bit about how an engine of a motorcycle works in the first place. Don’t worry, I am NOT going to ask you to take twenty Bachelors and eight Masters level courses for that, I have taken all of them so that you don’t have to 🙂

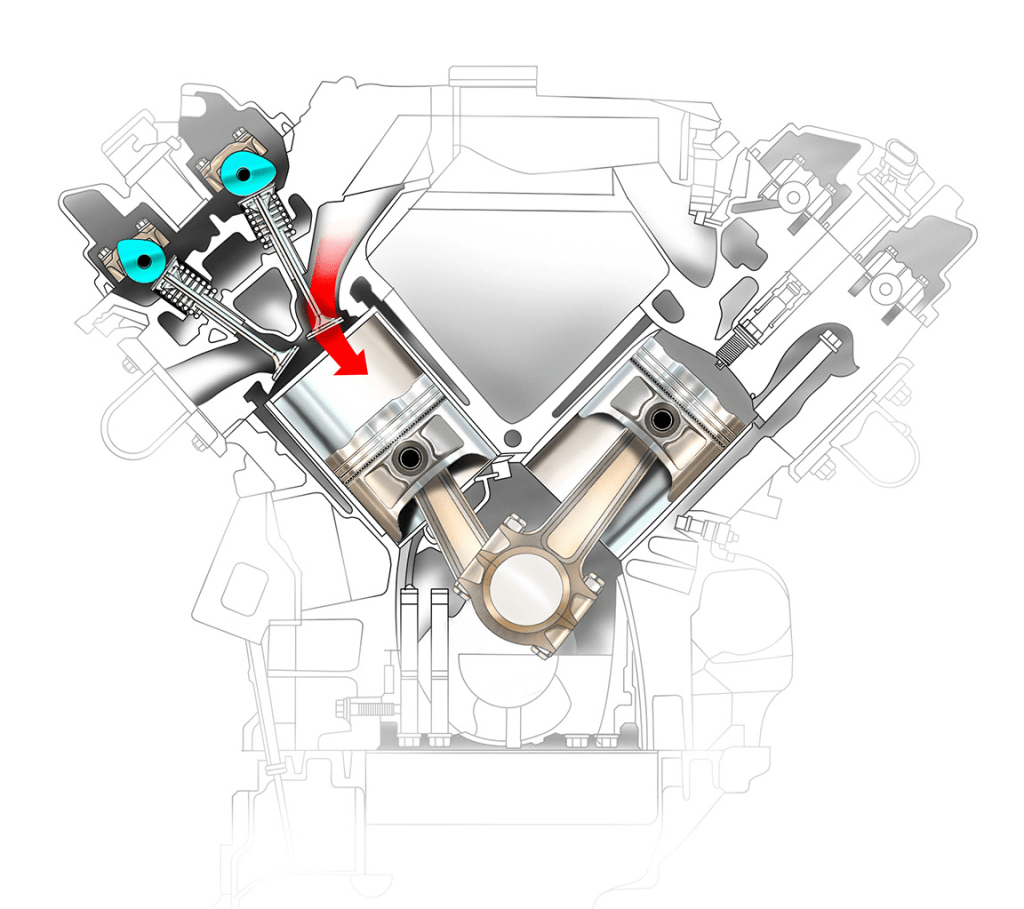

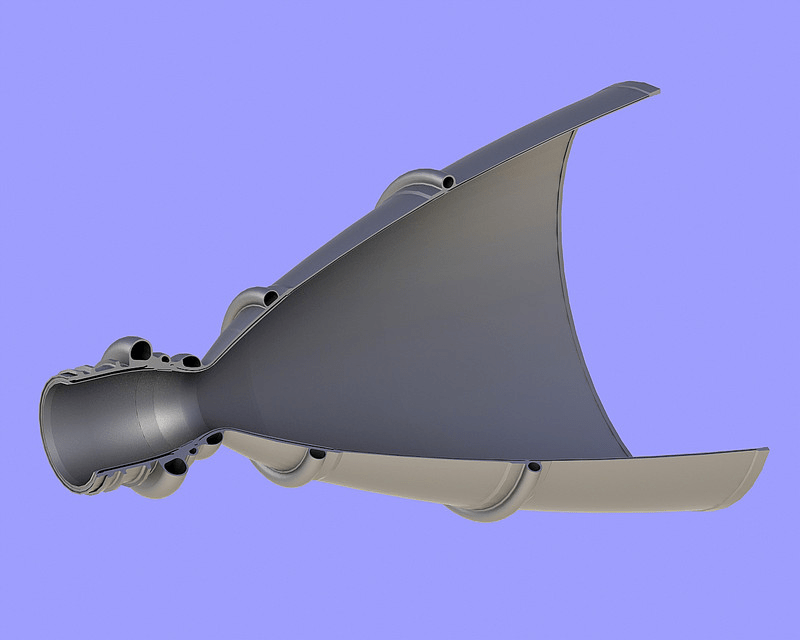

Most modern bikes, whether it is two-stroke or four-stroke engine consists of the same building components, slightly different to account for different thermodynamic cycles. Every engine consists of a crankshaft which converts the reciprocating motion of one or more pistons into circular motion and delivering it to the gearbox of the vehicle. The piston oscillates inside a cylindrical bore where the combustion takes place. Now depending on the capacity of the engine, there could be one or more such cylinders powering the crankshaft. The most famous example with a configuration of two pistons delivering power to the crankshaft is the Kawasaki Ninja 300.

The cylindrical bore is covered by the Cylindrical Head which does a lot of different things to keep a bike up and running. From keeping the combustion chamber closed, provide inlet for the fuel discharge to enter and outlet for the exhaust to move out of the engine. To achieve all this synchronously, the cylindrical head is accompanied with timings chain systems which by the help of simple yet complicated chain-pulley coupled with cam follower mechanism keeps opening and closing of inlet and outlet poppet valves in check.

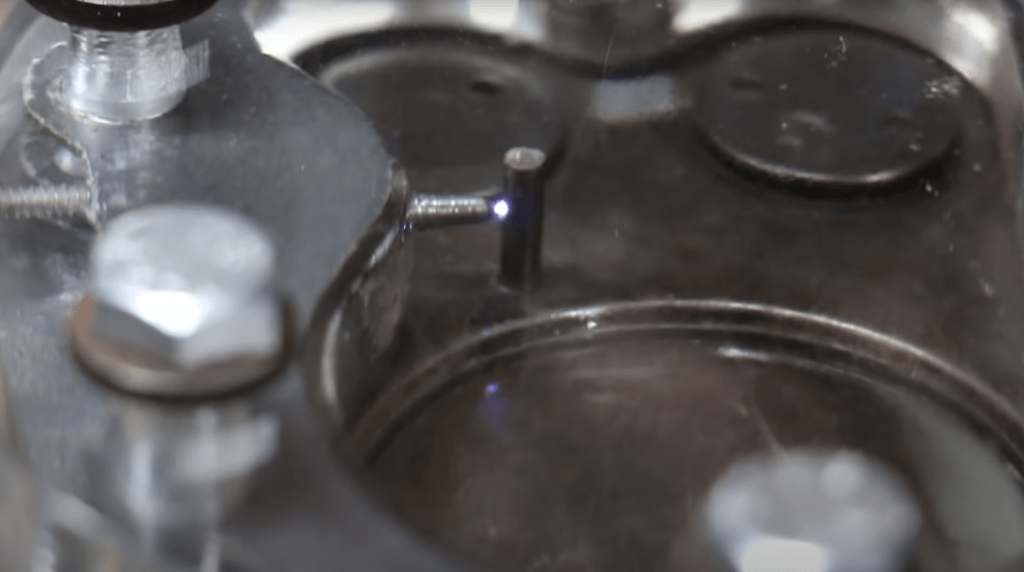

Destin from Smarter Everyday cover the working of an engine in the following video, where you can see the complete four strokes of the engine in Slow Motion. Before you head towards the video, I will mark the important features for you to look at.

Firstly, the bright spot on the vertical rod is actually an electric spark acting as the ignition energy required to start off the combustion process. The gap is selected such that the voltage required to breakdown the medium inside releases enough energy for the fresh charge to ignite.

Secondly, the larger bore (or hole) is for the piston to reciprocate, and lastly, two smaller hole covered by poppet valves which can move up and down, allowing the flow of fluid and restricting the flow of fluid, respectively. One of them is the inlet and the other one is conversely the outlet.

Now we are ready for enjoying quite an “energetic” sensation.

Why was the Ducati magic even needed?

Now that we understand the fundamental building block of a four-stroke engine, we can bring our attention to the problem with it.

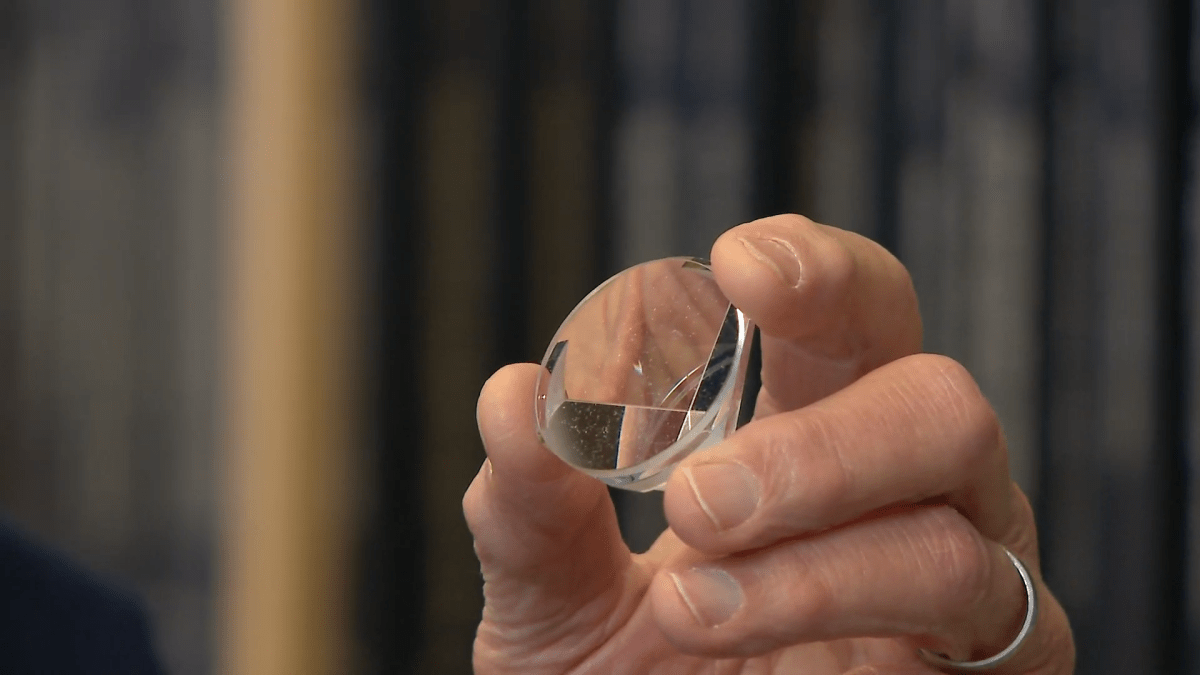

You see, the performance of an engine is dependent on a lot of factors, ranging from the charge supply, ignition coil, Cylindrical wall temperature and the timings of the poppet valves opening and closing. We clearly saw that we push the poppet valve using a cam follower mechanism which is also synced with the crankshaft mechanically. But here comes the catch! How does the poppet valve closes itself? Any guesses?

If you watched the cross sectional image and the explanation in the video by Destin, it will not be hard for you to point out that, the answer is simply “Springs”. When we push the valve the spring get stretched and applies a restoring force on the valve to pull it up. When the cam follower moves away from the valve, this restoring force of the spring pulls back the poppet valve in its natural closed position. Ok! But where is the problem with this?

What is wrong with Springs, Again?

Though it may originally appear that there should NOT be any problem with this setup and it is exactly the case when the piston is reciprocated at lower speeds (i.e. Lower RPM).

Side Mechanical Note: Introduction of a spring in the system makes it “laggy”. What does that even mean? Imagine you ask your friend to hold a spring from one end and you are holding the other end of the spring. You ask your friend to pull the spring towards themself, naturally you will feel the pull from the spring, but the important thing to note is, the pull will be delayed. And this is the PROBLEM!

This lag between cam moving away from the valve and the spring actually pulling the valve is what makes the engine problematic at higher RPMs. Still don’t agree with me, watch the video where the RPM of the engine is raised slowly and the motion of the spring controlling the poppet valve is also shown.

What did you observe? Initially the springs were responding on time with the cam motion but as the RPM increased the springs fail to react to the pace set by the cam which is driven by the crankshaft to begin with. This lag is commonly known as the “valve float” condition which eat away the delivery of the power by not allowing the charge to NOT get compressed tightly while igniting and it further allows the exhaust gas to stay inside the chamber in intake stroke thus degrading the charge inside the combustion chamber washing away the power delivered by the engine.

To understand how Ducati solved this, stay tuned for the next issue release. What they did is simple yet very powerful!

TL;DR.

Generated using AI

- Ducati’s Reputation: Known globally for its luxury and performance, Ducati’s renown stems from its Italian roots and its association with high-performance, premium superbikes.

- Engine Basics: Understanding a motorcycle engine involves basics like crankshafts and pistons which convert motion and power the vehicle through various mechanical components.

- Engine Complexity: The engine includes a cylindrical bore and a head that manages fuel intake and exhaust emissions, with timing chains and cam follower mechanisms to control valve operations.

- Visual Aid: Descriptions of engine components and operations can be enhanced with videos and diagrams, like those from Smarter Everyday which show the engine in action.

- Mechanical Challenges: High RPM operations introduce problems like valve float, where mechanical delays in valve operations reduce engine efficiency and power output.

For a deeper dive into how engines work and Ducati’s unique approach to solving common mechanical issues, you can watch the detailed explanation in the video: How Engines Work, Smarter Everyday on YouTube. Stay tuned for further exploration of Ducati’s innovative solutions to these challenges in upcoming content.

Leave a comment