Once the disruptor of the automotive market, equipping the machines with unbeaten power delivery at the higher engine speeds, the almighty desmodromic valves would ever face a down fall is quite hard to imagine. Maybe that is what is called Scientific Advancements knowing when to stop worshipping an idea and move to the next big thing.

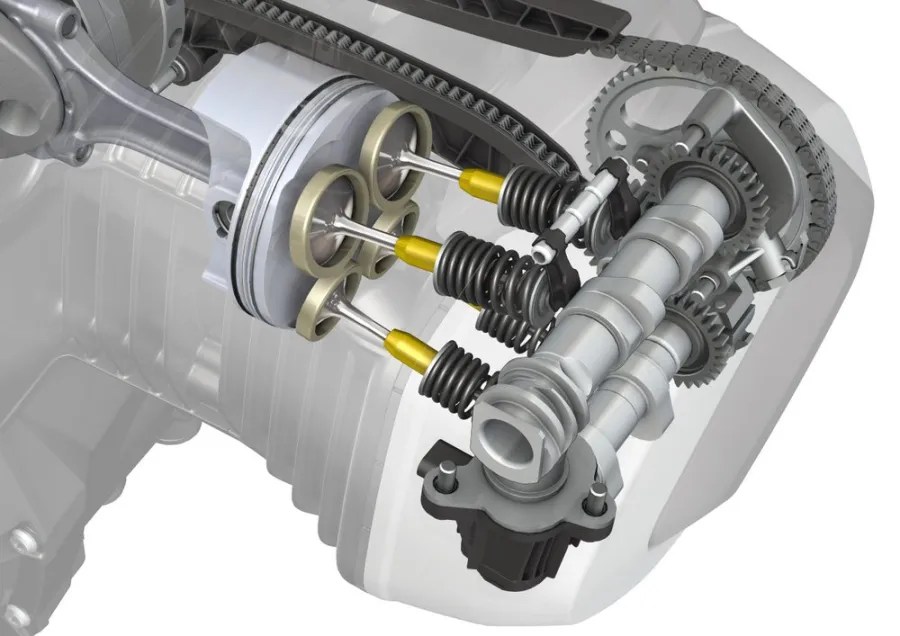

In the last article we talked about the REBIRTH of the desmodromic valves by Ducati and how this innovation helped Ducati to “dominate the racing world on Sundays and sell their bikes on Monday”. The unique offering of this kind of valves was to eliminate the laggy spring from the poppet timing chain system by using another cam to push the poppet valve back to close the inlet/outlet again, thus increasing the repeatability of combustion at higher RPMs.

While these offerings were hallmark of engineering prowess of Fabio Taglioni, the legend who made Desmodromic dream of Ducati a reality, it posed other issues along the way. Though, these issues were overshadowed by the success it gave to Ducati in the racing world, but this might not be case when we talk about the daily use of this red machine.

The Flip Side of Desmo.

Now we know what worked, but what didn’t work for Ducati? This is exactly what we are going to discuss here.

Introduction of the cam based retraction of poppet valve increased the complexity of the engine. One more set of cam timing mechanism was necessary to be driven from the crankshaft, the advantage as well as the disadvantage in achieving the perfect timing cycle, in comparison to a simple spring. But once designed and tested for qualification engineering complexity wouldn’t be an issue.

The issue was what came after designing, testing, manufacturing and delivering, the after sales service! Now there were twice as many components to be accessed, inspected, replaced, and verified. This meant longer labor hours at the service center and more components to be serviced, which at the end boiled down to hefty maintenance cost.

The Non-Ducati Way.

It was NOT the case that only Ducati wanted to achieve higher engine RPMs, every other manufacturer understood the complexity and the necessity of better valve systems. Do all of them leaned to Desmodromic Valve? NO! Did they achieve higher RPMs anyways? YES! Think of the Yamaha R6, a screamer that can rev up to 16,000 RPM, it never used desmodromic valves. It didn’t need to. Metallurgy has come a long way since the 50s, and springs can now keep up with insanely fast-turning cams.

While Ducati was developing Desmo, other manufacturers were also pushing the boundaries in automotive Research and Development. The following are some of the notable technology emerged in the same hustle.

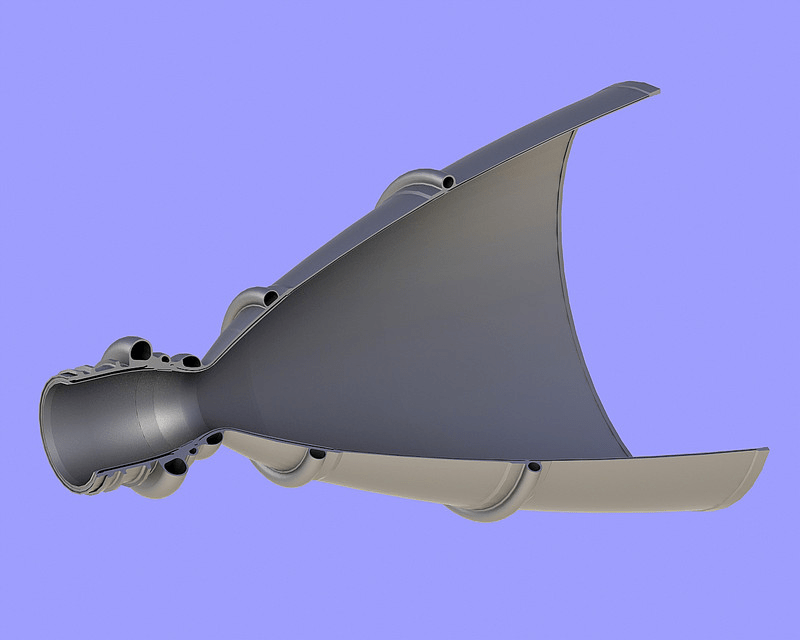

Pneumatic valves: Pneumatic Valves operate using compressed air to close the valves, replacing traditional springs or mechanical actuation. This system is highly efficient at ultra-high RPMs, providing unmatched response times. Formula 1 engines are a prime example, utilizing pneumatic valves to achieve speeds of up to 20,000 RPM. This technology is favored in specific racing applications for its precision and speed.

Advanced Spring-Based Systems: Modern spring-based systems have made remarkable advancements with the use of lightweight materials like titanium. These materials reduce inertia and improve responsiveness, allowing the traditional valve systems to handle high RPMs reliably. The Kawasaki Ninja H2, for instance, employs high-performance spring-based valves, delivering exceptional power and speed while maintaining reliability. This innovation significantly reduces the need for alternative systems like desmodromics.

Variable Valve Timing (VVT): Variable Valve Timing dynamically adjusts valve timing based on engine RPM and load conditions, offering a blend of high performance and fuel efficiency. Motorcycles like the Yamaha YZF-R1M and BMW S1000RR use VVT systems to optimize power delivery across different riding conditions. Unlike desmodromic valves, VVT is equally suited for everyday usability and high-speed performance.

Electromechanical Valves: As an emerging technology, electromechanical valves use electric actuators for valve operation, eliminating mechanical lag and wear entirely. While still in experimental stages, this system promises ultimate precision and control. These valves could revolutionize engine design, paving the way for a new frontier in valve technology, both in automotive and motorcycle applications.

The Ducati Way.

While other than Italian and some of handpicked automotive manufacturers, everyone else did not look desmodromic valve system as their preferred choice. Ducati is still nurturing the Desmo technology because of their long running tradition.

Once haunted for their frequent valve servicing with spine chilling maintenance costs in the earlier air-cooled engines, Ducati has come a ling way already. Further improvements in the metallurgy allowed the engineers to select material which could take the test of heat while being lightweight. Introduction of liquid-cooled thermal management system further bumped up the life of the valves. With other material selected for camshafts, the servicing duration started to match to that of the spring loaded timing systems from other manufacturers. While Ducati perfected the Desmo and its application in the racing world and still continues to do so, where every millisecond is important to be able to sell bikes on Monday, now they are shifting to spring based system for their mid-capacity bikes, while keeping MotoGP, Panigale, and Streetfighter still running on Desmo.

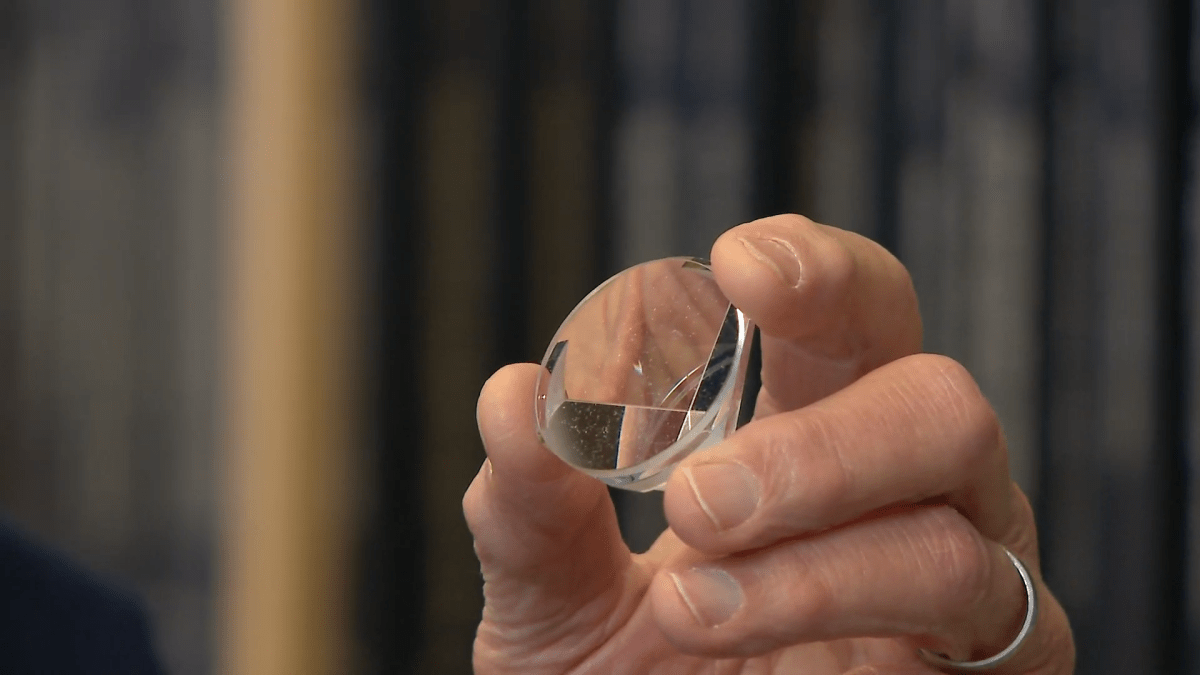

This is something I loved, keeping their Desmo heritage alive while adapting to the new advancements and molding the innovations accordingly. And YES, the material science has come a long way to tackle valve-float and durability using advanced materials like, Chromium-Silicon Steel (CrSi), Titanium Alloys, Inconel, Silicon-Chromium-Vanadium Alloys, and Carbon Nanotube-Enhanced Composites, and finally designed in the form of “springs”!

Helix of Life! Did you get it? Aaah Let it be 🙂

TL;DR.

Generated using AI.

- Innovation: Ducati’s desmodromic system uses cams instead of springs for valve control, enhancing engine performance at high RPMs.

- Challenges: Increased mechanical complexity leads to higher maintenance costs and longer service times.

- Alternatives: Manufacturers like Yamaha and BMW use advanced spring systems and variable valve timing to achieve high RPMs without desmodromics.

- Technological Advances: New materials and technologies, such as electromechanical valves, are emerging to potentially replace mechanical systems.

- Ducati’s Approach: Ducati continues to use desmodromic valves in high-performance models while adopting traditional valve systems in mid-range bikes due to advancements in material science and valve technology.

Leave a comment